Aluminium blasted coloured-anodised: more resistant than ever

Following in-depth studies over several years, German hardware company FSB has given fresh vigour to one of its favourite materials – aluminium. To achieve this, an innovative surface finish technology was used, improving both the aesthetics and functional properties of the material. FSB refers to the finish as ‘Blasted Aluminium Colour Anodised’ to describe a result product from lengthy development and manufacturing tests: anodised colours in the form of satin matt aluminium finishes blasted with fine shot whose inimitable sheen and pleasant haptic quality lend them an allure of a kind never before seen.

In technical and functional terms, blasting an aluminium surface causes it to be compacted much in the same way as during forging. As a result, blasted anodised aluminium finishes are somewhat more resistant to knocks and scratches than traditionally worked and anodised aluminium.

The anodised colour range at FSB refers to the classic metallic colours with which the builders’ hardware sector had endeavoured since the 1950s to emulate typical real hardware metals by means of colour-anodised aluminium finishes. What used to be an attractively priced alternative for private builders’ clients unable to afford (or unwilling to buy) door fittings in solid brass or bronze has, however, since established itself as a design option in its own right for architecture and select interior finishing schemes.

Current design trends, such as the drop in popularity of classic silver aluminium tones in the automotive industry, become more and more prominent also in window and door sectors. A conscious attempt to relate to the actual metal is made – “colour” in the sense of “colourful” is out. This is regardless of whether the host surface is highlighted by means of a metallic colour/finish or whether it is to play a more downbeat role – notably in the case of anodised or powder-coated window and facade profiles – as part of a scheme of coordinated shade.

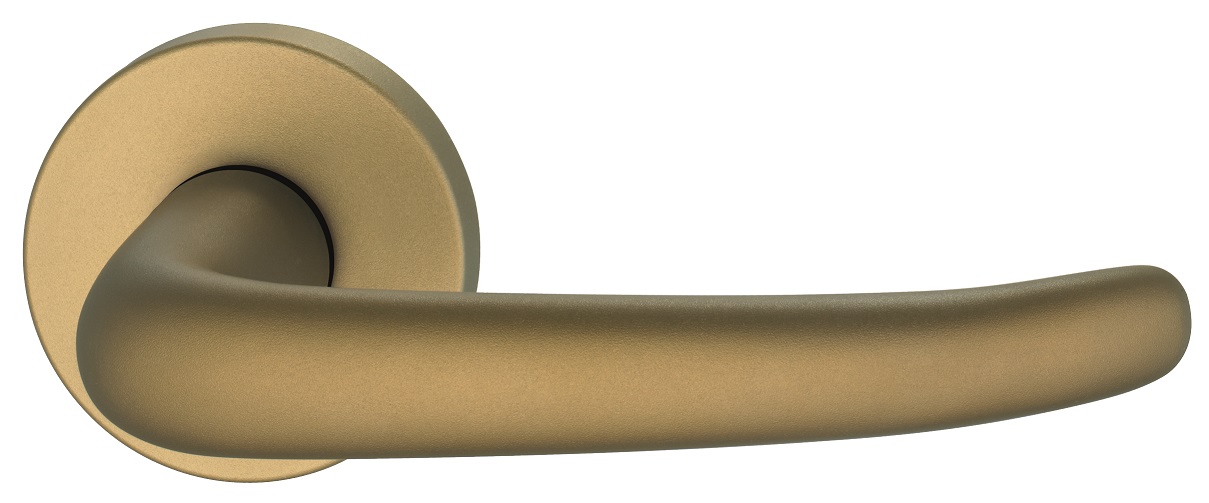

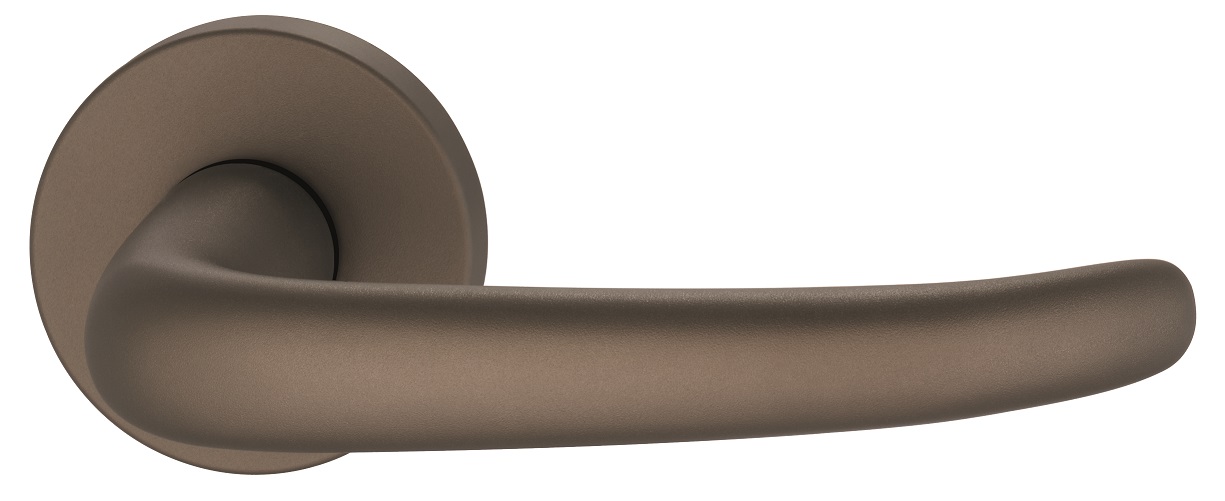

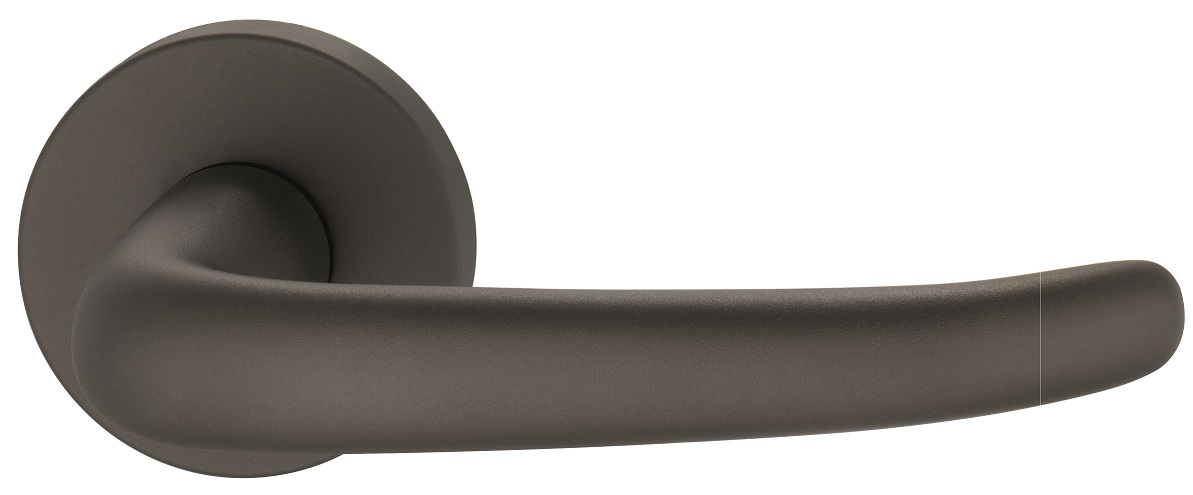

FSB offers a suitable range for this style, too: the new blasted matt surface with its inimitable sheen as a harmonious addition to a unified colour scheme. What is more, FSB does not focus solely on the aforementioned typical ‘real’ hardware metals and on emulating their various patina effects in aluminium, but includes also the most popular façade finishes: C33 and C35 (EURAS). The new aluminium surface finish thus certainly broadens the scope of design options.

|

|

|

|

| S4 BRONZE TONE | S5 MEDIUM DARK BRONZE TONE (C33) | S7 DARK BRONZE TONE (C34) | S8 BLACK (C35) |

These blasted aluminium colour anodised surface tones are available for all FSB aluminium handles.

History: aluminium + FSB

Right from the start, aluminium has been used as a high-tech material, when light weight and high durability are required. Space travel as well as aircraft and car manufacturing are inconceivable without it and it was responsible for making some innovations possible in the first place. Especially in the second half of the 20th century, aluminium started its triumphal advance into interior design and into design in general. Its technological mystique together with its silvery, glittering surface opened up new horizons in the use of metal in interior design and practically laid the groundwork for the rapid success and popularity of stainless steel.

However, the market demand steadily increases for various alternatives in design, particularly for standout design features or for when a client is slightly bored of the “always perfect” look of stainless steel.

Some of the FSB aluminium handle collections are still based on the 1920s know-how of aluminium processing. Over the years, specialists at FSB have perfected these techniques with the complex organisation of processes involving an efficient combination of both manual work and industrial production. This way aluminium can be turned into handles of any shape, whether it is a classic of strict geometry or one of Johannes Potente’s masterpieces echoing the organic shape of a hand. As a result, each aluminium handle is a product of the original label ‘(Hand-)made in Germany’, and a carefully crafted, unique design object.